Abstract

A systematic research was developed in European countries regarding the use of nano-structured suspensions in stone monuments for their consolidation and protection. The treatments were based on nanoparticles suspended in water or alcohol, also in combination with alkoxy silanes. Five cathedrals, in different climatic contests, and one contemporary building were involved in the validation of products. The effectiveness evidenced not only a dependence on the lithotype, but also on environmental constrains. In general, the nano-particles presence enhanced the capacity of the treatments to adhere to stone grains, thus contributing to their effectiveness.

Nano-cathedral general achievements

On the European contest the development of liquid nano-treatments for deteriorated stones was carried out up to the validation in relevant environment in the framework of the H2020 NANO-CATHEDRAL project, concluded on 2018.

The aim of NANO-CATHEDRAL project was developing, on an European scale, new nano-materials, technologies and procedures for the conservation of deteriorated stones in monumental buildings and cathedrals and high value contemporary architecture, with a particular emphasis on the preservation of the originality of materials and on the development of a tailor-made approach to tackle the specific problems related to the different lithotypes. Aggregation of stone monuments representatives of different European climatic regions and different styles and lithotypes were considered.

Nano-additives and nano-structured composites were developed suitable for:

- Surface consolidation [1-3], occurring thanks to a material that penetrating by capillarity into the micro-structure of the decayed stone, is able to strengthen it by replacing lost original mineral bridges, and partially recovering lost mechanical properties.

- Surface protection [4-5], occurring thanks to a material that penetrating by capillarity into the micro-structure of the stone, is able to prevent the ingress of liquid water, without any change in aesthetical, optical and chemical properties of the substrate.

The preparation and selection of the nano-structured treatments was carried out with the aim of providing the best technological answer for the preservation of different types of stones found in the selected cathedrals representative of the diversity of European architectural heritage. For reaching the goal of consolidation, water-based formulations based on nano-inorganic or nano-hybrid dispersions such as nano-silica, nano-titania, nano-hydroxyapatite as well as their synergic combinations with organic (e.g. fungal hydrophobins) and inorganic compounds were considered. Stone specimens, both as aged in situ (small or micro-samples) and as obtained on purpose from the original quarries (taken as such or after accelerated aging), was tested before and after application of the consolidation and protection materials to evaluate the effectiveness of the treatment, according to relevant European standard protocols [6], current scientific literature and the development of new in situ testing procedures.

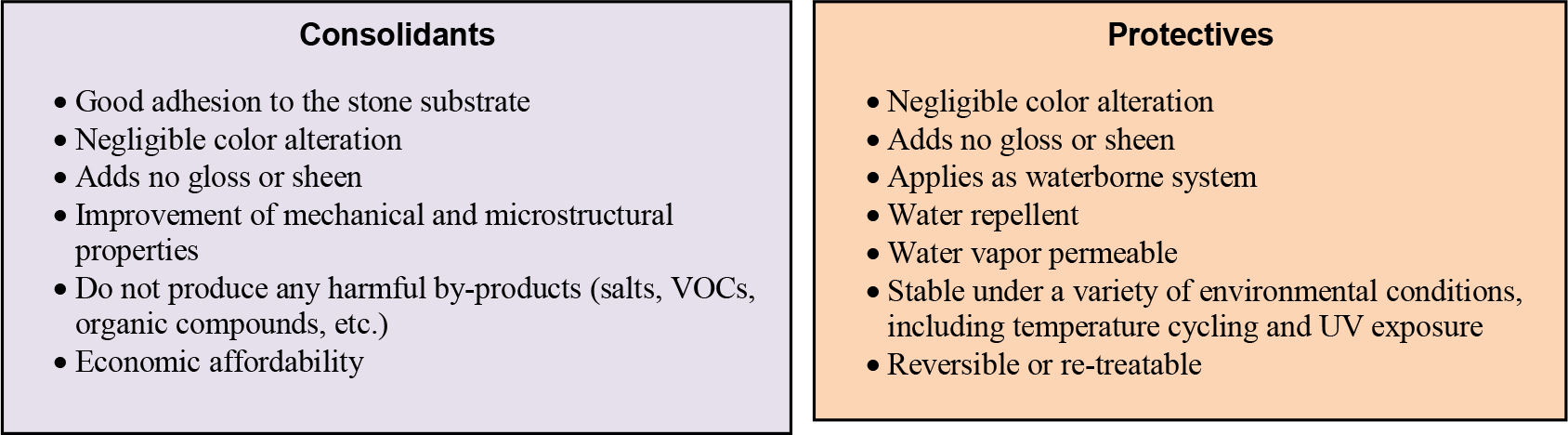

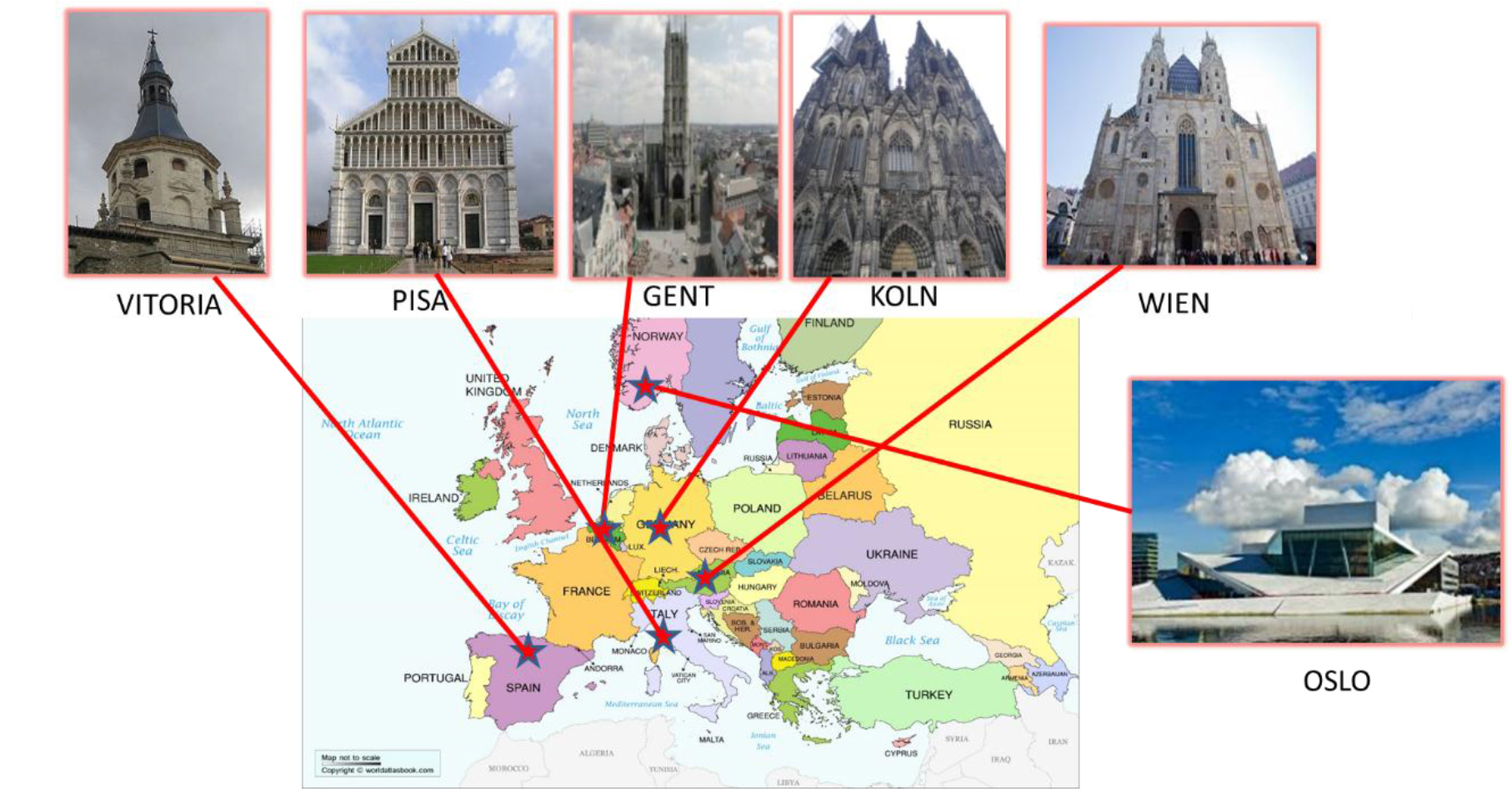

To achieve the goal of stone protection, innovative composites were developed consisting of polymers and nano-fillers; the use of hydrophobins, nano-assembled hydrophobic proteins extracted from fungi [7], was also considered. The nano-structured protective materials were designed to achieve improved soil and water-repellence. In addition, photocatalytic nano-particles were employed in order to favour the decomposition of volatile organic molecules carried by polluted atmosphere and to prevent biofilm growth. The specific requirements for consolidants and protectives are reported in Figure 1. The innovative products were applied on 6 lithotypes (Ajarte fossil limestone, Balegem sandy limestone, Obernkirchen and Schlaitdorf sandstones, St. Margarethen calcareous arenite and Apuan marble) (Figure 2), selected among the stones used in five medieval cathedrals (Vitoria-Gasteiz, Ghent, Cologne, Vienna and Pisa) and a contemporary opera theatre (Oslo Opera House). The six places are also representative of the different European climates and environments (Figure 3).

Figure 1. Characteristics of consolidants and protectives

Figure 2. Representative stones selected for the experimentation of Nano-Cathedral project

Figure 3. Involved European towns and respective monuments

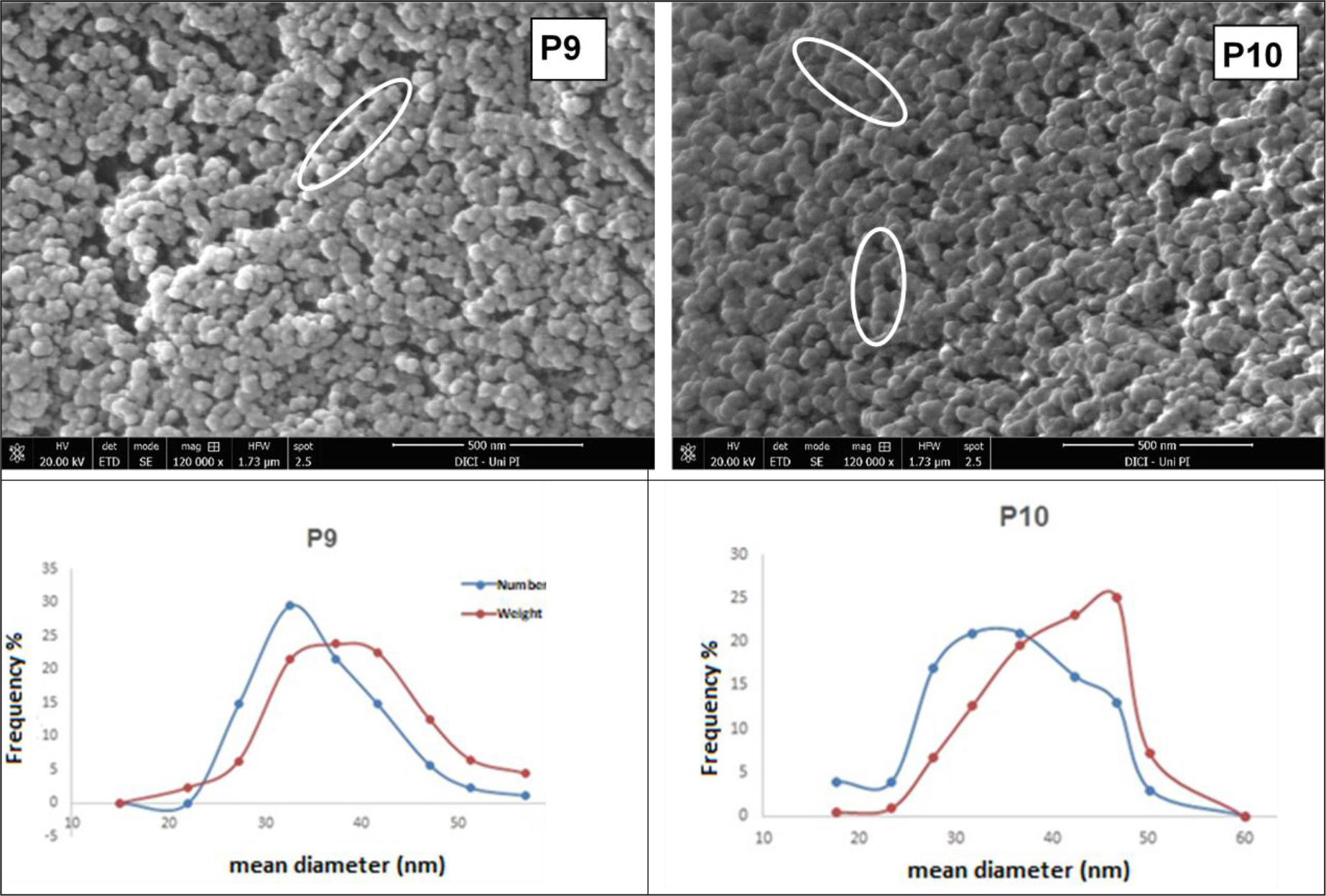

Figure 3. Above: SEM micrographs of dried powders of CCNPs from samples P9 (left) and P10 (right) with the corresponding particle size distributions (below; the red line connects the weight averaged frequency, the blue line the volume averaged frequency, from particle counts and sizing obtained through image analysis. Circles evidence “chain-like” assemblies of nano-particles.

Regarding the identification and development of nano-materials, it had the objective to make available nanomaterials formulations suitable as consolidants and protectives for each of the selected lithotypes to the laboratories for the characterization and to the cathedrals for the application (in small scale before and on site later). A list of consolidants and protectives has been preliminary identified and sent to all the monuments foundations responsible of their preservation for further validation. Then, taking into consideration the results provided by the laboratories dedicated to the testing of consolidants and protective treatments participating to the project, a selection was done. The selected products are reported in Table 1.

Table 1. Products selected for experimentations on the monument stones

|

Products selected for the validation in situ on specific lithotypes |

Product internal code |

Producer |

Type |

|

ZG 12 (SiO2 in Ethanol/Water) |

NC-12C |

COLOROBBIA |

CONSOLIDANT |

|

ZR110 (ZrO2 in water) |

NC-29C |

TECNAN |

CONSOLIDANT |

|

HFES 70 (Si Polymer matrix with TiO2 from Tecnan)) |

NC-25C |

CHEMSPEC |

CONSOLIDANT |

|

HFES 90 (Si Polymer matrix with TiO2 from Tecnan)) |

NC-27CP |

CHEMSPEC |

CONSOLIDANT |

|

PFA (Si Polymer matrix with TiO2 from COLOR)) |

NC-21P |

CHEMSPEC |

PROTECTIVES photocatalytic |

|

PFMS5 (Si Polymer matrix with TiO2 from COLOR) |

NC-22P |

CHEMSPEC |

PROTECTIVES photocatalytic |

|

Antibacterial TECNAN (ZnO/Ag) |

NC-32P |

TECNAN |

PROTECTIVES Anti-fouling |

|

P01_INSTM |

NC-36P |

INSTM |

PROTECTIVES hydrorepellent |

Four consolidants were tested onto monuments based on nano-silica (ZG 12), nano-zirconia (ZR110), or nanotitania in presence of alkoxy silanes less (HFES 70) or more (HFES90) hydro repellent. They were compared with tetra theoxy silane (TEOS) as it is the most known and used consolidant. Four protectives were selected for testing onto monuments: two photocatalytic products acting against pollution to maintain clean the stones Some more nano-structured materials were also developed in the project activities. Regarding consolidants, nano-calcite was produced using a pilot reactor [8]. The preparation of water suspensions of calcite nanoparticles (CCNPs) was carried out using a pilot-scale reactor by controlled carbonation of slaked lime. A simplified design of experiment was adopted for product optimization. Calcite nanoparticles of narrow size distribution averaging about 30 nm were successfully obtained, the concentration of the interfacial agent and the size of CaO being the most critical parameters. Primary nanoparticle aggregation causing flocculation could be substantially prevented by the addition of polymeric dispersants. Copolymer-based dispersants were produced in situ by controlled heterophase polymerisation mediated by an amphiphilic macro-RAFT (reversible addition-fragmentation transfer) agent. The stabilized CCNP aqueous dispersions were then applied on carbonate and silicate substrates; Scanning Electron Microscopy (SEM) analysis of cross-sections allowed the evaluation of pore penetration, interfacial binding, and bridging (gap-filling) properties of these novel consolidants.

The effectiveness of the obtained nanocalcite suspensions as potential consolidants for deteriorated calcareous and siliceous stone substrates was investigated in preliminary experiments, in which the CCNP aqueous dispersions were applied onto model porous substrates. Stratigraphic SEM analyses have shown only partial and irregular product penetration within the porous network, but also good adhesion of the precipitated CCNPs, as shown by the effective formation of bridges efficiently connecting stone grains. Shrinkage of the consolidating film upon drying was almost negligible in the treated Au limestone and only moderate in the silicate samples. The uneven CCNP distribution throughout the porous stone network, along with local accumulation of the consolidant at the edges of the treated stone specimens, was ascribed to rapid evaporation of the treating solution; in order to overcome this problem, a more thorough investigation to define the best application protocol will be required.

It is worth pointing out that further improvements concerning both the CCNP production process and their colloidal stabilization or even encapsulation with suitably designed copolymers may further improve the elasticity and cohesivity of the nanoparticle-built bridges within the pores. The results obtained so far, while limited to the application on only two reference substrates, do not yet allow the anticipation of a significant short-term strengthening effect of the CCNPs, in particular because of the observed low penetration depth and the lack of scientific studies regarding the chemical bonding of calcite nanoparticles with either carbonate or siliceous substrates. Thus, while some reduction of the overall porosity could be achieved, proper mechanical strengthening still needs to be confirmed.

Regarding Hydrophobic treatments, semi fluorinated water born polymers, designed and prepared to induce a nanostructured internal morphology in the polymer particles, with a hydrophobic semi fluorinated core and a hydrophilic-shell rich in either nonionic oligoethyleneoxide or anionic oligo(acrylic acid) chain end segment, were characterized (P01_INSTM). The Laboratory application and validation produced an extensive and sound information on the performance of the most promising nano systems (consolidants and protective treatments) applied on the selected lithotypes. After a pre-selection of the products and the preparation of the laboratory samples, the application of the most promising nano systems as well as selected reference products and their full validation was carried out within the second period of the project.

As laboratory-produced specimens can never mimic the full range of decay phenomena found on-site, small-scale consolidation and protective treatments have been performed by experienced conservators from the project team on pilot areas of the five cathedral sites and of the Oslo Opera House (here only protective treatments).

Artificial ageing tests were carried out on stone specimens treated with selected consolidants and protective coatings. Besides, the evaluation of the durability of these treatments, conducted through artificial ageing protocols, allowed to make an experimental assessment of their response towards environmental exposure, with overall encouraging results.

All necessary information from the sites, including the results gained by the laboratory analysis of samples extracted as small scaled drill cores by in situ lithotype sampling was collected to prepare detailed operational guidelines for the preparation of sites. These guidelines should ensure a structured cleaning procedure for various stone surfaces before starting the in situ application of the products. In order to have the stone surfaces freshly prepared for application, the preparation of the trial areas was performed in timely proximity to the availability of the products determined as the final selection of testing materials. The validation of in situ treatments at each site started one month after the application process. In beforehand, to assess the performance of the selected products before the product application, a protocol of control tests was set up, including colour measurements, water absorption by contact sponge and karsten tubes, drilling resistance, microscopic and macroscopic observations and microclimatic monitoring. After application, the treatment evaluation at the trial areas was carried out according to this protocol.

To summarize the outcome of the extensive validation work is complex. An overall conclusion towards the new developed products and nano composites can be, that the nano particles in solution confer slighter improvements in the treated substrates than the micro particles; nevertheless, the acceptable results obtained during the project are in need of further research. In general, the validation results achieved after the products application on site are only partially in accordance with the validation results from the laboratory tests; moreover, application of identical products on the same lithotype but in different areas of the building, delivered results. For each lithotype the outcome must be evaluated on its own, considering the decay extension and the physical features, as well as the allocation and background parameters. HFES70 (based on nano-titania particles and TEOS) seemed the consolidant suitable for general use, as it resulted acceptable onto silicate stones but it scarcely formed bridges between stone grains, whereas nano-silica in ethanol (NC-12C) has the general defect of less penetration but is more efficient in bridges formation.

Regarding metamorphic stone consolidation, only the combination of nano-silica and TEOS consolidants achieved very good results. As for the sedimentary stones, the results vary considerably from site to site and must be assessed individually; for this type of stones the nano silica in combination with TEOS appeared to be the most suitable product in terms of cohesion, nonetheless the visual compatibility, for instance, must be improved. Apart from this product, the other combinations of TEOS with nano titania showed only good results in Ajarte. The selected protectives based on nano-titania resulted very promising, both on sedimentary and metamorphic stones. The anti-fouling product was compatible with all lithotypes where it was applied (some sedimentary stones). The innovative protective based on acrylic semi-fluorinated copolymer resulted only partially effective on the sedimentary stones.

Conclusion

The use of nano-structured liquid treatments containing nanoparticles was investigated for application in decayed stones of cultural heritage on an European scale in the framework of H2020 Nano-Cathedral project. New consolidants and protectives were produced for stone monuments and tested onto selected representative lithotypes in laboratory. Many of them were used in successive validation studies onto monuments, where their effectiveness evidenced not only a dependence on the lithotype, but also on environmental constrains. Some other nanostructured treatments were developed up to a lower readiness level, but resulted promising, such as nano-calcite nano-particles. In general, the nano-particles presence enhanced the capacity of the treatments to adhere to stone grains, thus contributing to the effectiveness of the treatments.

Acknowledgements

This research was carried out in the frame of the EU-H2020 project “Nanomaterials for conservation of European architectural heritage developed by research on characteristic lithotypes (NANO-CATHEDRAL)”, GA 646178.

References

- Dohene E, Price CA, Stone Conservation. (2010) An Overview of Current Research, Getty Conservation Institute, LA (USA).

- Mosquera M.J, de los Santos D.M, Montes A, Valdez-Castro L. (2008) New nanomaterials for consolidating stones. Langmuir, 2772–2778.

- Ban M, Mascha E, Weber J, Rohatsch A, Delgado Rodrigues J. (2019) Efficiency and Compatibility of Selected Alkoxysilanes on Porous Carbonate and Silicate Stones, Materials 156.

- Gherardi F, Goidanich, S., Toniolo, L. (2018) Improvements in marble protection by means of innovative photocatalytic nanocomposites, Progress in Organic Coatings, 13–22.

- Roveri M, Raneri S, Bianchi S, Gherardi F, Castelvetro V, et al. Electrokinetic Characterization of Natural Stones Coated with Nanocomposites for the Protection of Cultural Heritage, Applied Sciences, 194.

- CEN/TC 346WG3 Evaluation conservation works methods & products for on porous inorganic materials constituting cultural heritage.

- Boeuf S, Throm T, Gutt B, Strunk T, Hoffmann M, et al. (2012) Acta Biomaterialia 1037–1047.

- Coltelli MB, Paolucci D, Castelvetro V, Bianchi S, Mascha E, et al. (2018) Preparation of Water Suspensions of Nanocalcite for Cultural Heritage Applications, Nanomaterials 254.